D2 Tool Steel Heat Treatment

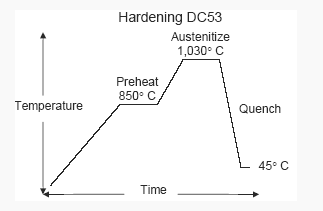

D2 tool steel heat treatment. Preheat the steel by slowly raising the temperature to between 750 and 780 degrees Celsius. SEM micrograph of D2 tool steel heat treated in controlled atmosphere furnace at 1038C30min and tempered at 593C 12hn showing the. Then cool in the furnace at 20F 10C per.

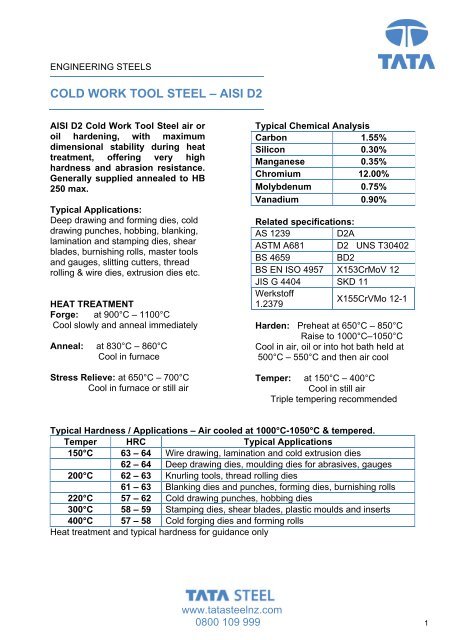

The D2 steel was heat treated and ground by Devin Thomas. D2 tool steel is an air-hardening cold work high carbon high chrome tool steel with exceptionally high wear resistance properties. D2 Tool Steel is a versatile high-carbon high-chromium air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous large chromium-rich alloy carbides in the microstructure.

Some shops anneal late in the day after all other heat treating has been finished by. It offers excellent abrasion resistance due to a large volume of carbides in the microstructure. Be careful to not tear or puncture the wrap.

Heat Treatment Process Involved In D2 Steel. How to Heat-Treat D2 Steel Step 1. To limit distortion and stresses in enormous or complex tools use a double preheat.

D2 is widely used in long production cold work applications requiring very high wear resistance and high compression strength. All were heat treated with a 30 minute hold time plate quench and cryo followed by a double temper. Heat at a rate not exceeding 400F per hour 222C per hour to 1150-1250F 621-677C equalize then the heat will comes to 1400-1450F 760-788C.

D2 tool steel properties combine minimal distortion in heat treatment high toughness and wear resistance at the expense of grindability and machinability compared to. D2 tool steel is a high carbon high chromium air-hardening tool steel that can be heat treated to high hardness and compressive strength. D2 offers excellent wear and abrasion resistance due to large volumes of carbides in the microstructure.

D2 is a high carbon - high chromium air hardening tool steel heat treatable to 60-62 Rc. Industeel Trademark - D2 - 102017 3 HEAT TREATMENT After machining service properties of D2 should be restored by hardening.

I dont have exact temperatures but it looks like you might want to go a bit over 600 degrees to temper.

The D2 steel was heat treated and ground by Devin Thomas. All were heat treated with a 30 minute hold time plate quench and cryo followed by a double temper. D2 is not a steel that can be heat treated in the kitchen oven it requires too high of a temperature to temper. Then cool in the furnace at 20F 10C per. Heat at a rate not exceeding 400F per hour 222C per hour to 1150-1250F 621-677C equalize then the heat will comes to 1400-1450F 760-788C. HEAT TREATMENT SOFT ANNEALING Protect the steel and heat through to 1560F 850C. It is also available in the form of hollow bar and rings. It is recommended to perform. SEM micrograph of D2 tool steel heat treated in controlled atmosphere furnace at 1038C30min and tempered at 593C 12hn showing the.

HEAT TREATMENT SOFT ANNEALING Protect the steel and heat through to 1560F 850C. D2 is widely used in long production cold work applications requiring very high wear resistance and high compression strength. For oil quenching the temperature should be between 65 -. D2 tool steel properties combine minimal distortion in heat treatment high toughness and wear resistance at the expense of grindability and machinability compared to. The PSF27 specimens were heat treated by Michael Drinkwine. Once wrapped place in the furnace and heat. Of the steel and quality heat treatment are key factors in order to develop tools or parts with the enhanced properties that only tool steel can offer.

Post a Comment for "D2 Tool Steel Heat Treatment"